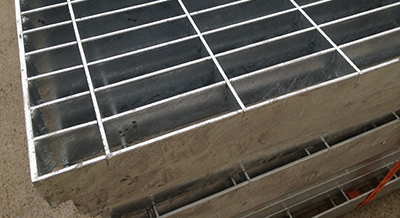

Bar Grating End Banding

BAR GRATING

END BANDING

Why is Bar Grating End Banding Important?

Bar Grating end banding is a welding process that closes open bearing ends of bar grates. It is the best way to give your metal grating a more finished look while also giving it greater industrial strength. Keep reading to learn more about the advantages of end banding and the different types.

What is End Banding?

At Marco Specialty Steel, we specialize in different types of bar grating. Bar grating comes standard with open-end construction. For all types of bar grating products, end banding is a process that brings uniformity and protection to all the open ends of metal grating. End banding maintains panel structure and prevents injury during installation.

How is Banded Grating Welded?

A flat bar of the same primary material, height, and thickness as the selected grating bars is cut to the dimension of the panel or pieces. Then, the flat bar is welded to open bearing bar ends. This provides a uniform appearance around all sides of the grating panel, closing off any gaps along the edges.

If you are in need of more welding info, feel free to download our welding standards for banding pdf file.

Banded vs Unbanded Grating

If your industrial bar grating does not have banding, the bars can bend over time and cause premature failure of the grate. Unbanded bar grating should be used for foot traffic applications only. In general, banding should be added to any application with heavy traffic to reduce impact stress. See examples of banding in our fabrication photo gallery.

There are Several Advantages to Adding Banding

The end banding process adds a finished architectural appearance and can prevent bearing bars from warping over time. Many applications of bar grating would benefit significantly from edge banding to provide additional stability.

Here are the main advantages to bar grating end banding:

Strengthen and support: There are 2 applications where end banding should always be used; for vehicle traffic and for removable grating panels. The additional bars add to the transverse stiffness of the grating by transferring load weight to adjacent bars and reducing stress. Banding bars should be installed when the ends of bearing bars are not supported.

Protection and safety: To protect yourself and others, end banding gives the panels a smooth finish and will prevent injury when moving the grate. Compared to standard grating, the flat sides around the perimeter will make it much smoother and easier to pick up.

Enhancement of appearance: If you want to give your bar grating a more complete and upscale look, then add end banding. The closed-off edges of this type of grating provide an excellent architectural appearance that will greatly enhance the design in any area where it’s used.

Different Types of End Banding, Load vs. Trim

Depending on the final application and intended use of bar grating, two banding methods can be employed: standard trim banding and load banding.

Trim Banding

Trim banding is fitted with flat metal bars that are welded at each corner and every fourth or sixth bearing, depending on the width of your piece. Standard trim end banding improves your product’s appearance and enhances its stability for foot traffic applications only. It is a cost-effective, lightweight option, and can be a great way to keep people from getting hurt on your property.

Load Banding

Load banding (also known as load-bearing banding) is different from standard trim banding by adding a flat bar to every single end of the bar grating panel. A full perimeter around the bar grate locks the bar grate in place and prevents it from bending or twisting under high stress.

Load bands are often used in grating applications to bear heavy, industrial weight. For example, this method is frequently employed in places where high levels of automotive traffic or forklift activity are anticipated. Load banding protects the structural integrity of the bearing bars by helping them resist significant, recurring pressures.

Note: It is essential to choose the right end banding to ensure the structural integrity and safety of your bar grating system. With the right end banding in place, you can be confident that your bar grating will perform optimally for years to come.

Our Fabrication Services

Still not sure which type of end banding is right for you? Marco Specialty Steel is here to help. Our fabrication specialists are ready to assist with bar grating end banding. To learn more about how we can provide bar grating modifications, we invite you to contact us today!