Marco Specialty Steel is a trusted supplier of various Perf Safety Grating accessories. Browse our products below and contact us for a quote.

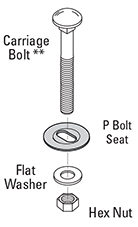

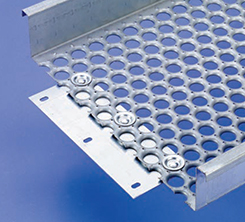

Perf Safety Grating Bolt Washer Seat

Perforated Grating Bolt Seats help provide a secure anchor of the grating to structural supports. The standard bolt seat features oblong holes specifically designed to help ensure a vertical anchor (with a 3/8” bolt) even if the hole is off concentrically by as much as 1/4”.

- Item Includes: (1) Bolt Washer Seat

- Order Separately:

(1) 3/8”-16 Carriage Bolt **

(1) 3/8” Flat Washer

(1) 3/8”-16 Hex Nut - Field drilling is required

** Plank carriage bolt lengths = Side Channel Height + 1”.

Walkway carriage bolt = 5/16”-18 x 2”.

Hardware is not provided.

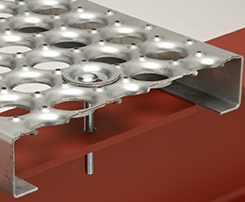

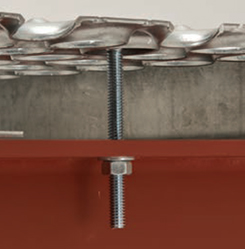

Assembly

- Align planks on I-Beam or other anchoring cross-member.

- Mark the I-Beam for drilling purposes under the hole nearest the end. Drill a pilot hole.

- Remove plank and drill a finish hole.

- Replace plank to its original position. Place bolt seat in the hole which is now lined up with the drilled hole.

- Run the carriage bolt through the bolt seat, perforated grating and I-Beam, and tighten with washer and nut until secure.

- Test for movement or slippage. If planks are not secure, check fastening system for loose or missing parts. Repeat steps 1 thru 5.

Note: Do not walk on planks if they are not secure. Serious injury could result.

Welding

A common method of fastening safety grating is welding. It is recommended that all Safety Grating products be fillet welded per AWS D1.3.

For more information, consult Technical Services.

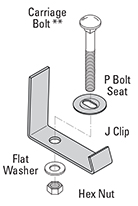

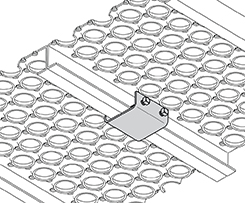

Perf Safety Grating J-Clip

Perf Safety Grating J-Clips fasten the grating securely to the supporting steel without drilling holes. Standard finish is galvanized.

Hardware is not provided.

- Item Includes: (1) J-Clip & (1) P Bolt Seat

- Order Separately:

(1) 3/8”-16 Carriage Bolt **

(1) 3/8” Flat Washer

(1) 3/8”-16 Hex Nut

** Plank carriage bolt lengths = Side Channel Height + 1”

Walkway carriage bolt = 5/16”-18 x 2”

Assembly

- Align planks on I-Beam or other anchoring cross-member.

- Place bolt seat on center hole of nearest the overhanging end.

- Align J-Clip below plank so that the carriage bolt can slide through. Make sure the lower lip of the J-Clip reaches well into the I-Beam.

- Run the carriage bolt through the bolt seat to the J-Clip and tighten securely with the washer and nut.

- Test for movement or slippage. If planks are not secure, check fastening system for loose or missing parts. Repeat steps 1 thru 4.

Note: Do not walk on planks if they are not secure. Serious injury could result.

Welding

A common method of fastening safety grating is welding. It is recommended that all Safety Grating products be fillet welded per AWS D1.3.

For more information, consult Technical Services.

Perf Safety Grating Mid Support Clip with Hardware

Perf Safety Grating mid support clips can be used at midspan to increase load carrying capacities of individual channels by fastening several planks together to form an integral section. Mid support clip is manufactured from galvanized steel and includes two set screws.

- Item Includes: (1) Clip & (2) Set Screws

- Order Separately:

(1) 3/8”-16 Carriage Bolt **

(1) 3/8” Flat Washer

(1) 3/8”-16 Hex Nut

Assembly

- Align planks on I-Beam or other anchoring cross-member.

- Place clip around the bottom flanges of the planks.

- Slide to the required location.

- Tighten the set screws.

- Test for movement or slippage. If planks are not secure, check fastening system for loose or missing parts. Repeat steps 1 thru 4 as required.

Note: Do not walk on planks if they are not secure. Serious injury could result.![]()

Welding

A common method of fastening safety grating is welding. It is recommended that all Safety Grating products be fillet welded per AWS D1.3.

For more information, consult Technical Services.

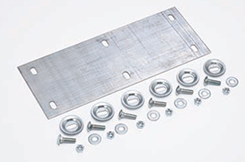

Perf Safety Grating Splice Plate Kits

As the width increases, grating surface performance becomes more critical. Thus, for Perf Safety Grating product widths greater than 12”, use of the grating surface splice kit is recommended to mechanically join butt ends of plank sections.

- Hardware Included: 3/8” x 1” carriage bolts, 3/8” flat washers, and bolt seats.

- POG-ES-10 (for 18” wide plank) & POG-ES-13 (for 24” wide plank) includes six (6) each of hardware shown below.

- POG-ES-16 (for 30” wide plank) & POG-ES-20 (for 36” wide plank) includes eight (8) each of hardware shown below.

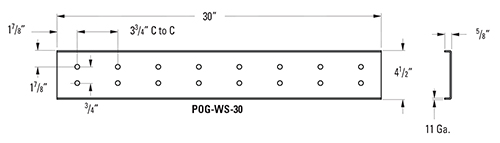

Perf Safety Grating Walkway Splice Plate Kits

Walkway Splice Plates provide continuity when multiple lengths of Perf Safety Grating are desired. Connections are reinforced with the addition of splice plates attached to side channels.

- For 24”, 30” and 36” wide walkway.

- Each Kit Includes: Two (2) splice plates and thirty-two (32) each of the following hardware: 1/2” x

11/4” hex bolts, 1/2”-13 hex nuts, and 1/2” flat washers.

Supplying All Your Grating Needs

Marco Specialty Steel is proud to supply and fabricate the most comprehensive line of safety grating products including Diamond Safety Grating, Perf Safety Grating, and Tread Grip with slip-resistant surfaces.

We are the number one go-to for grating products, therefore we also stock bar grating and fiberglass grating.

Contact Us for a Free Quote Today!

Please contact one of our friendly, knowledgeable technical sales representatives to learn more about our Perf Safety Grating accessories and to receive a no-obligation project quote.